Australia isn't any stranger to fire-related disasters. Country Experience more than 17,000 residential fires per 12 months.

The use of heaters and candles every winter increases potential fire hazards. Combine this with our already fire-prone vegetation, and customarily hot and dry climate, and you'll be able to see why there's an urgent must develop effective and sustainable fireproofing methods.

This is what inspired our research team. Make fireproof material Made from edible fungi. These materials can resist flames to guard the integrity of the constructing structure (and any occupants).

Our work presents an exciting opportunity for an industry that has spent an excessive amount of time using materials which can be harmful to human health and the environment.

Fireproofing through the a long time

In the Nineteen Seventies, chemicals were widely utilized by construction firms in AustraliaHalogenated flame retardantsFrom fireproofing buildings, to furnishings and electronics.

These flame retardants, which Contains a large scale Chemicals containing bromide or chlorine are effective in stopping combustion. But has been related to many individuals Adverse health effects including immunotoxicity, reproductive toxicity, cancer and impaired neurological function.

Phosphorus and nitrogen-based flame retardants are preferred over their halogenated counterparts and are still used for fireproofing today, including in Australia. However, these also pose some threat to human health and nature (through toxicity and accumulation within the environment).

Finding a greater alternative

Our team has. developed a fabric made entirely of mycelium, which shows great promise for fireproofing.

Mycelium is the root-like structure of fungi. It is made up of many thin, branched filaments. The cell partitions of those filaments are largely composed of a natural polymer called chitin (which you can too find in crab shells and bug exoskeletons).

Shutterstock

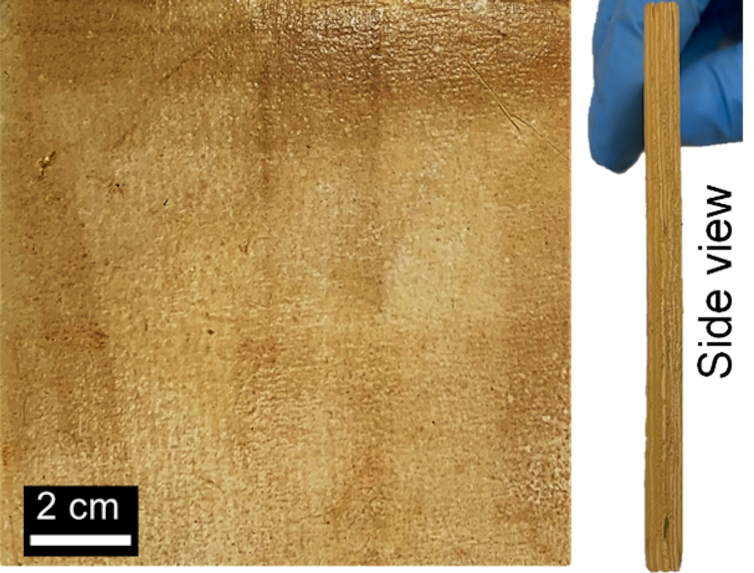

Our mycelium-based material is lightweight, eco-friendly, biodegradable and has a comparatively long ignition time.

When exposed to intense fire or heat, the fabric can turn to char — a black high-carbon residue that continues to be when all of the water and volatile compounds are burned. It is just like the charcoal that continues to be after burning wood. This char protects any primary flamable material by reducing heat transfer and stopping further combustion.

Unlike existing fireproof materials, our material only releases harmless natural products, comparable to water and carbon dioxide, when exposed to fireside.

A flexible material

Our material is flexible and may be folded to numerous thinnesses, including all the way down to a 1 mm thin wallpaper. This makes it more useful than a bulky cookie. Bricks Our group was created first.

It may be used as thin sheets like wallpaper, or it may possibly be assembled into thick and powerful base materials that resemble wood or cladding.

We display two potential applications for the constructing and construction industry (although there shall be other uses in industries comparable to automotive and aerospace engineering):

-

Only as fungal sheets laminates, where the thickness may be customized, can be ideal to be used as insulation panels.

-

Fungal layers attached to the surface of flamable structures, just like wallpaper applied to partitions, improve fire protection.

Next Steps

Although mycelium-based materials are currently used for construction worldwide, Packaging and insulation, none are commercially available yet. Moreover, none have been used or approved for fireproofing.

We have been approached by the mushroom industry to develop our material and its commercialization feasibility. Collaboration shall be critical to making a closed-loop industry where agricultural waste may be transformed into sustainable biomaterials that meet fire safety requirements.

Our product has a protracted option to go before it may possibly be bought off the shelf, and we are going to must overcome various challenges of mass manufacturing in the method.

Nevertheless, we hope that our work can ultimately contribute to a future where fires in buildings are significantly reduced, and where our homes are safer and more sustainable places to live.

Leave a Reply